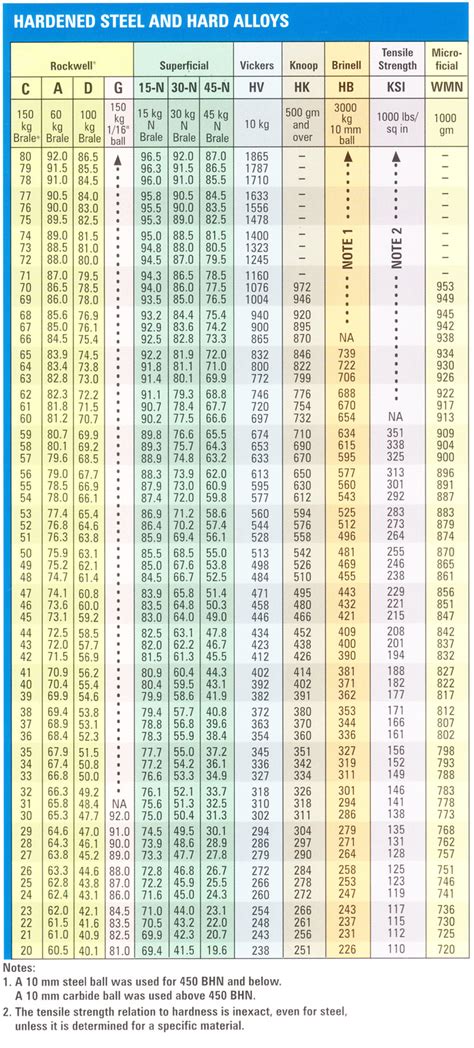

hrb hardness test|brinell to rockwell hardness chart : trade Rockwell HRB Vickers HV N/mm²; 3000kg 10mm Ball 150kg Brale 100kg 1/16" Ball . Diamond Pyramid 120kg. Tensile strength (Approx) Reference table: Steel Hardness conversion chart. Since the various types of hardness tests do not all measure the same combination of material properties, conversion from one hardness scale to another is only an . WEBFuso horário de Boston. 00:08:58 AM. ter., 13/02/2024. Fuso horário. UTC -05:00. EST. Diferença de tempo. 13 horas atrás Pequim. DST de Boston em 2024. EST. UTC-0500. .

{plog:ftitle_list}

webOur GRP (Glass Fibre Reinforced Plastics) Tank systems offer our customers greater flexibility with temperature ranges and chemical barriers. The tanks are manufactured using a range of isophthalic and vinylester resin.

rockwell hardness scale chart

When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a steel ball (1.59mm or 3.18mm in .Rockwell HRB Vickers HV N/mm²; 3000kg 10mm Ball 150kg Brale 100kg 1/16" Ball . Diamond Pyramid 120kg. Tensile strength (Approx) Reference table: Steel Hardness conversion chart. Since the various types of hardness tests do not all measure the same combination of material properties, conversion from one hardness scale to another is only an .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .

Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71

mohs scale of hardness chart

hrc scale chart

Defining Correction Factors. ASTM Standard E18 also has tables for defining correction factors when testing cylindrical shapes (see Figure 2).The corrections vary according to the sample's diameter and hardness and can be as much as six points on the HRC scale and 12.5 points on the HRB scale.Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . case-hardened steel, shallow case-hardened steel, cemented carbide, other materials with relatively low hardness. HRB: Ø1.588mm Hardened Steel Ball: 980.7 (100) 20-100: Soft metals, non-ferrous metals, annealed steel, aluminium alloys .

HRC (Rockwell C Hardness) and HRB (Rockwell B Hardness) are scales measuring material hardness; HRC is used for harder materials, HRB for softer materials. New; General; Language; Business; Science; Technology; . HRB testing with a steel ball indenter is effective for softer metals. 10. HRC.

HRB – This scale is used to test aluminum and other softer steels. It uses a 1/16-inch steel sphere. iii. HRC – For this scale, a diamond indenter is used to apply 150 kgf to heavy steel materials. . A hardness test’s immediate result is that you will eventually get to the material’s breaking point. Even tests when the specimen breaks . HS<100HB<500HRC<70HV<1300 (80~88) HRA, (85~95) HRB, (20~70) HRC Rockwell hardness in HRA, HRB, HRC, etc. A, B, C are three different standards, called scale A, scale B, and scale C. Rockwell hardness test is one of several common indentation hardness tests used today. The initial pressure of the three scales is 98.07N (10 kgf). Rockwell hardness number (HRA, HRB, HRC, etc) Leeb hardness value (HLD, HLS, HLE, etc) . Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a .

It employs a hardened steel ball as the indenter and a 100kg weight to obtain a value expressed as "HRB". The C-scale, for harder materials, uses a diamond cone, known as a Brale indenter and a 150kg weight to obtain a value expressed as "HRC". . ISO 6508-1 : Metallic materials -- Rockwell hardness test -- Part 1: Test method (scales A, B, C . The hardness of aluminum can be assessed through various testing methods, including Brinell hardness and Rockwell hardness. The hardness of aluminum alloys is related to the other metals they are alloyed with, such as magnesium, manganese, and copper. . HRB: HBA; 1: Alpase K100-S™ Plate: 11.4: 62: 69; 2: Alpase K100™ Plate: 11: 60: 68; 3 .

white label Box Compression Tester

The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously elevated hardness value. . In addition, NIST is planning to standardize the HRB scale using tungsten-carbide balls. As a result of this change, this edition .

It is impossible to define a single conversion method using different hardness test methods. That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. . Rockwell B 100kgf (HRB) Vickers (HV) (HBS) 10mm Standard ball 3000kgf . Because the indentation ball is so much larger than in other testing methods, hardness values derived from the test provide a more representative average hardness of the part. More information about Brinell testing can be . When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a .(Examples: 64 HRC = Rockwell hardness number of 64 on Rockwell C scale; 72 HRBW = Rockwell hardness number of 72 on Rockwell B scale measured using a tungsten carbide ball indenter.) The test must be conducted on a smooth, even surface that is free from oxide scale, foreign matter, and, in particular, free from lubricants.

Hardness test methods and hardness conversion tables Introduction. Hardness is a surface property where indentation, scratching or wear is resisted. The higher the hardness the more resistant is the surface, and the more difficult surface operations such as cutting and machining are. . Vickers Hardness (HV) Rockwell (HRB) Rockwell (HRC) UTS .The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface .

Certified Hardness Test Blocks are a requirement as a reference material for any type of hardness testing. Home; Products. Special Offers. . According according to the latest ASTM E18 (v. 2022) specifications. The tolerance on the HRB test blocks are as follows: If HRB is less than 88 the acceptable tolerance is +/- 2.5.A variety of hardness-testing methods are available, including the Vickers, Brinell . Rockwell B HRB (1/16" ball 100 kg) Leeb HLD [1] 800-72-856 780: 1220: 71-850 760: 1210: 70-843 745: 1114: 68-837 725: 1060: 67 . "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal conversion .

Rockwell Hardness (HRC and HRB) and Brinell Hardness (HB or BHN) are most commonly used for steel and iron castings. Although there is no accurate conversion tables and equations, but dandong foundry recommend the following formulas and comparison tables according to the experience and standards.

Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . HRB: Ball, 1.588 mm (¹⁄₁₆ inches) 98.07 N (10 kgf) 980.7 N (100 kgf) Copper . In stainless steel standards, three hardness testing methods, Brinell, Rockwell, and Vickers, are typically stipulated, measuring HB, HRB (or HRC), and HV hardness values respectively. It is specified that just one of the three hardness values needs to be measured for stainless steel hardness testing.

There are 30 different Rockwell scales with the majority of applications covered by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals. With the increasing use . For the lowest hardness test force, the 15 Kgf scales, a polished or lapped surface is recommended. Care should be taken when finishing any material .

hrb hardness means

Compre Mortal kombat komplete edition P/ XBOX360 (LTU/LT/JTAG/RGH) na Shopee Brasil! Jogo para Xbox 360 (as versões que consta no titulo do produto) Jogos que são dois dvds conta como dois jogos Todos os jogos são testado antes do envio para comprovação de funcionamento do mesmo. Obs. O funcionamento do jogo no console vai depender .

hrb hardness test|brinell to rockwell hardness chart